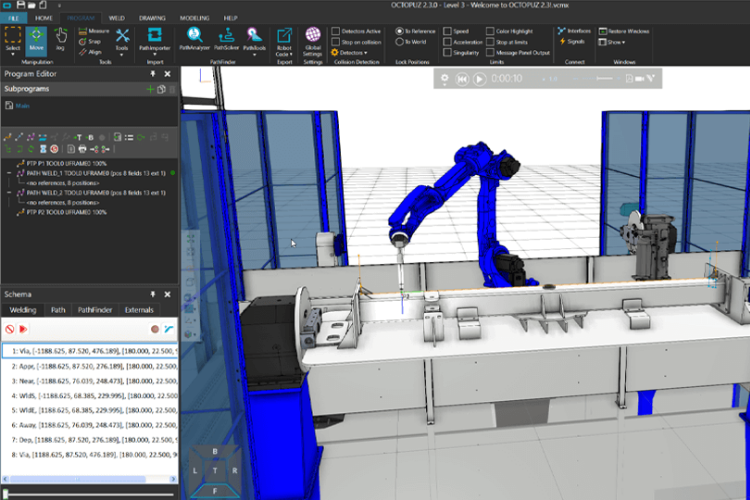

This system comprises a twin station single axis positioner with a handling capacity of 500 kg at each station. The twin station approach is the key to increased productivity due to the fact that the robot is welding during the operator load cycle.

The range of arc welding system, ArcSystems, are built to a standard that delivers savings in both time and money. They are based on a modular system of standard components that meet the requirements of the general and automotive industry using a minimum of floor space.

The robot choice is flexible depending on the application and there is a choice of safety system depending on customer requirements and available floor space. This may comprise a light guard system or an automatic roller shutter door in case of optimum floor space utilisation.