Octopuz delivers what its name promises: maximum flexibility and versatility or optimum simplicity and efficiency.

The team at YRobotics can design and simulate your manufacturing processes and plant layouts prior to any purchase of capital equipment. See your own products in real motion and in 3D!

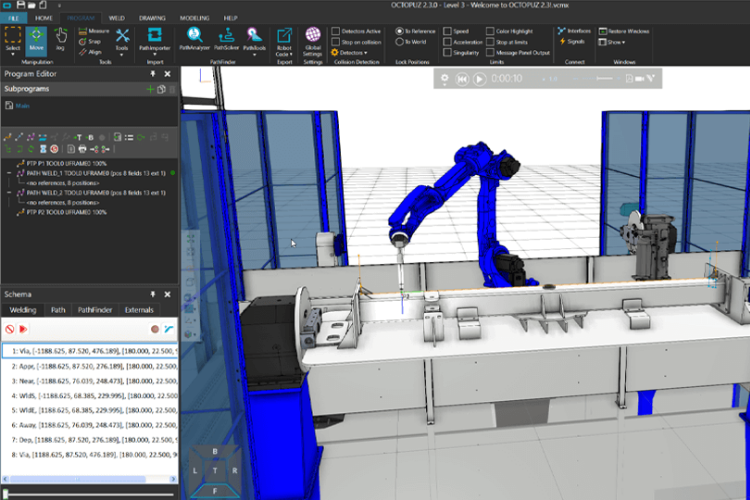

Octopuz takes a revolutionary approach to robotic programming by combining the offline programming of robotics with a manufacturing process simulation, making it ideal simulation software for any application.

Features of Octopuz give you all the tools needed for path-sensitive robotic applications, providing optimized external axis management and indicating the reach limitations while avoiding singularity.

OCTOPUZ Features

- Multiple robots? No problem!

Program, simulate and generate code for multiple robots, simultaneously, with support for many robot brands in any configuration.

- Software to Robot Integration

Program code generated from Octopuz can be input directly into the robotic controls.

- Complex kinematics systems

Not limited to 6-axis manipulators, Octopuz can support 3-axis scara robots up to 7-axis manipulators, external axes (linear rails, rotaries), conveyors, feeders and more!

- Our Customers

Octopuz is used and trusted around the world. Octopuz provides value each and every day to both Small and Medium Size Businesses and Fortune 500 companies!

- Application Versatility

Full software versatility allows for unlimited uses.

- Most robot brands supported

15+ brands supported with a regularly updated library.

- Simple simulation building

Drag, drop and snap components together from the library to make complex systems with pre-made logic.

- CAM interface

Program paths onto parts using your favorite CAM system and verify/create the motion for your robot system.